Tugboat News | TugIO | Cost Control & Operational Efficiency

Maximizing Tug Boat Repair with Data-Driven Predictive Maintenance Software

Read Time: 12 mins | Jun 19, 2025 1:44:11 AM | LionRock Maritime

Maximizing Tug Boat Repair with Data-Driven Predictive Maintenance Software

Data-driven predictive maintenance is transforming tugboat operations by leveraging real-time data, advanced analytics, and machine learning to anticipate maintenance needs. This approach reduces downtime, optimizes the maintenance schedule, and extends the lifespan of tugboats, improving safety, reliability, and cost efficiency. As digital tools evolve, predictive maintenance is becoming essential for achieving sustainable and competitive maritime operations.

Introduction – Predictive Maintenance Software For Tug Boat Repair

The maritime industry is constantly evolving, with technological advancements paving the way for more efficient and sustainable operations. As the demand for reliable maritime services grows, so does the need for innovative maintenance strategies.

The advent of digital tools has revolutionized how maintenance is managed, moving beyond traditional methods to more advanced, data-driven approaches. By leveraging machine learning, operational data analytics, and predictive health monitoring, companies can anticipate maintenance needs, reduce unplanned downtime, and extend the life of their assets.

With predictive maintenance software, operators can anticipate potential issues before they escalate, allowing for timely interventions that prevent costly breakdowns. This proactive, data-driven approach enhances vessel safety, reliability, and performance, offering a more efficient path forward for tug boat repair and management. By focusing on predictive insights, maritime operators can ensure that their fleets operate at peak efficiency.

Understanding The Functioning Of Predictive Maintenance Systems

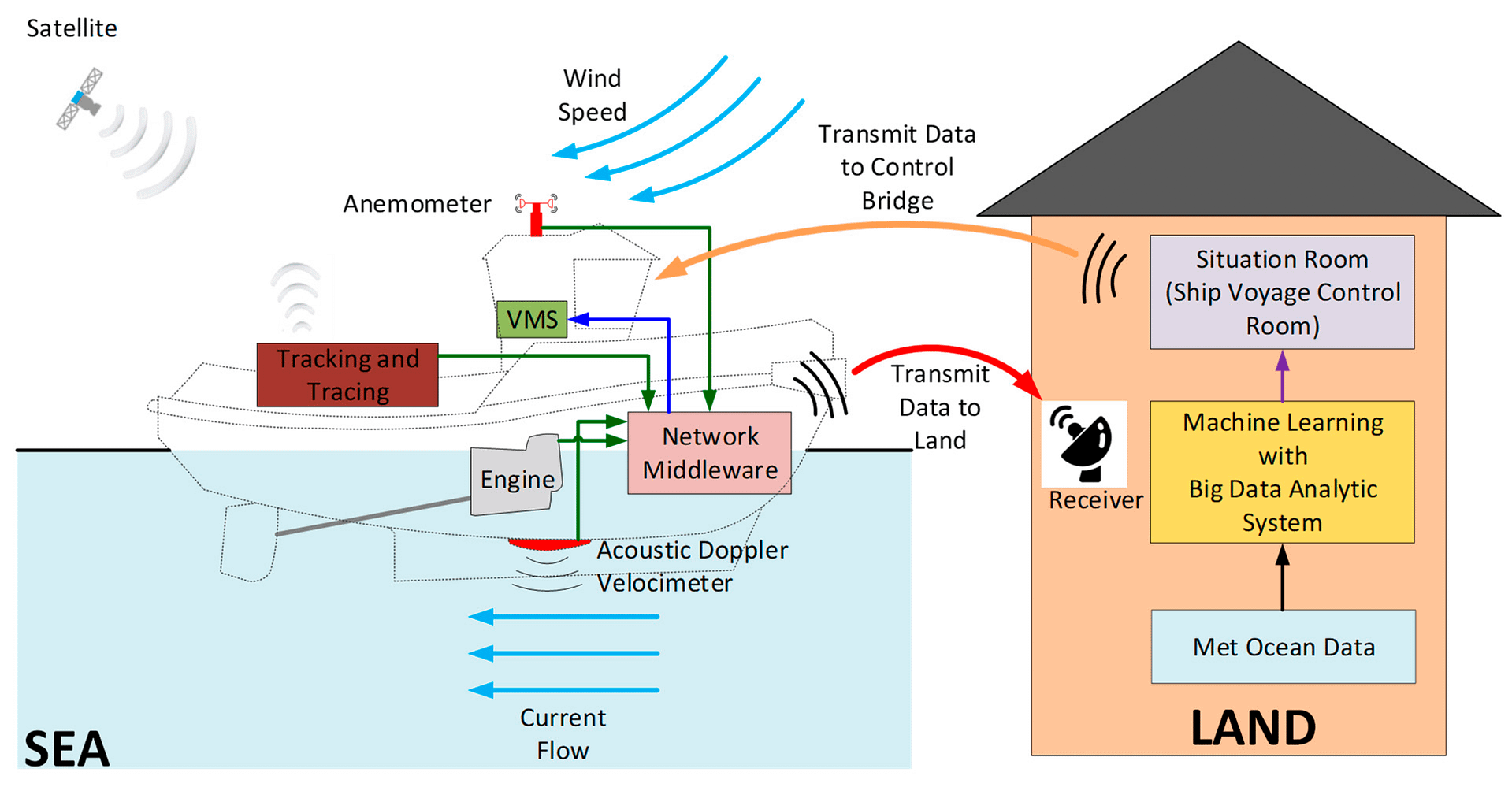

This diagram from 2021 depicts how a tugboat predictive maintenance system works, showcasing the flow of data between sea and land.

- Data Acquisition: Sensors on vessels collect data on key metrics like engine performance, vibration, and temperature, which is then transmitted in real time for processing.

- Data Processing: Raw sensor data is cleaned, standardized, and prepared for analysis, ensuring high-quality inputs for predictive models.

- Analytics: Advanced analytics and machine learning algorithms analyse the processed data to identify patterns, detect anomalies, and predict equipment failures.

- Decision Support: Insights from the analytics are used to generate actionable recommendations for maintenance, tug boat repair, parts replacement, and operational adjustments, enhancing decision-making.

- User Interface: A user-friendly interface presents these insights to operators, engineers, and fleet managers via dashboards and alerts, enabling quick, informed decisions.

The Power Of Data Analytics: Predictive Maintenance

Maintenance strategies in the maritime industry have traditionally focused on reactive and preventive approaches. Reactive maintenance addresses issues as they occur, while preventive maintenance follows a routine schedule to prevent failures. However, both methods often fall short in optimizing costs and tugboat work schedule. Predictive maintenance, although not new, has gained renewed importance due to advances in data collection and analytics tools. Today, the ability to gather real-time data from assets and analyse it with sophisticated software has significantly improved predictive maintenance capabilities. This evolution enables operators to detect potential failures earlier and more accurately, enhancing operational efficiency and reducing costs like never before.

Predictive maintenance builds on the foundation of preventive maintenance by incorporating real-time data and analytic software. Instead of performing routine checks or waiting for machinery to fail, predictive maintenance uses data gathered from sensors installed on key components to assess their condition continuously. Through this process, it becomes possible to detect early signs of wear or malfunction well before they lead to significant issues. This targeted strategy is particularly effective for critical or ageing equipment, where the risk of breakdown is higher. Unlike the routine nature of preventive maintenance, which is based on fixed schedules, predictive maintenance dynamically adapts to the actual condition and performance of machinery, allowing for a better tugboat work schedule.

Benefits Of Data-Driven Predictive Maintenance

1. Enhanced Safety: Regular maintenance not only improves performance but also ensures the safety of the crew and the vessel. Data-driven insights help in identifying potential safety hazards and addressing them promptly, reducing the risk of accidents.

2. Extended Tugboat Lifespan: Regular and timely maintenance helps in prolonging the lifespan of tugboats. By addressing issues before they escalate, the overall wear and tear on the vessel is minimized, ensuring that it remains in top condition for longer periods.

3. Cost Savings: Predictive maintenance reduces the need for emergency repairs, which are often more expensive than planned maintenance activities. By optimizing the maintenance schedule, operational expenses are significantly reduced, contributing to the overall profitability of maritime operations.

4. Reduced Downtime: One of the most significant advantages of using real-time data for predictive maintenance is the reduction of unplanned downtime. By predicting maintenance needs and scheduling them during non-peak times, the tugboat work schedule can be optimized, ensuring minimal disruption to operations.

Future Outlook And Industry Trends

As the maritime industry continues to embrace digitalization, the adoption of data-driven preventive maintenance is expected to grow. It is expected that the integration of innovative AI and machine learning into predictive maintenance software will further enhance its capabilities, making interventions even more accurate and timely.

As tugboat operators face pressures to minimize downtime and reduce costs, predictive maintenance emerges as a key focus for the future. Insights from industry leaders suggest that harnessing data not only enhances safety but also transforms how we think about vessel reliability and efficiency. Embracing predictive maintenance can shift the narrative from reactive repairs to proactive strategies, unlocking new levels of performance.

The adoption of advanced analytics is set to redefine the tugboat work schedule, allowing operators to anticipate issues and optimize operations.

Conclusion – The Role Of Predictive Maintenance Software

Data-driven predictive maintenance is revolutionizing how tugboat maintenance is managed. Traditional methods of reactive and scheduled maintenance are increasingly insufficient in today’s digital age. Advanced preventive maintenance schedule software now allows maritime operators to predict and address issues before they escalate, minimizing downtime and emergency tug boat repairs.

By using real-time data and analytics, operators can proactively manage the tugboat work schedule, ensuring maintenance aligns with operational needs. This leads to many benefits. Fewer breakdowns, for example, mean better resource utilization and improved service delivery, directly contributing to profitability.

Predictive maintenance not only saves costs but also offers a strategic edge by improving vessel reliability and sustainability. With its ability to continuously monitor equipment and detect early signs of wear, this approach ensures that tugboats remain in peak condition, ready for service when needed. Adopting these technologies is key for maritime operators looking to stay competitive and efficient in a rapidly evolving industry.

In this era of digital transformation, leveraging data as a cornerstone of fleet management ensures a more resilient, cost-effective, and future-ready maritime operation.

Unlock Peak Fleet Performance With LionRock And Techbinder’s Data-Driven Solutions

As the maritime industry moves toward a data-driven future, LionRock Maritime, in collaboration with Techbinder, is at the forefront of optimizing tugboat operations through cutting-edge predictive analytics. Techbinder specializes in installing advanced sensors and data loggers on board, which capture critical real-time information, including engine status and other key performance indicators. This partnership enhances the Tugboat Tracker System by LionRock, offering a comprehensive view of your fleet’s operational health.

By combining Techbinder’s data acquisition expertise with LionRock’s predictive analytics platform, the Tugboat Tracker System provides actionable insights that anticipate maintenance needs and extend the lifespan of your vessels. This integrated approach enables maritime operators to optimize speed, fuel consumption, and overall efficiency, ensuring smarter and more sustainable operations.

Embrace the future of maritime maintenance with LionRock Maritime and Techbinder. Leverage our combined solutions to transform your fleet management strategy and stay ahead in the competitive maritime landscape. Contact us today to learn how our partnership can elevate your operations to new heights.

Frequently Asked Questions

FAQ: Predictive Maintenance Software

What Is Predictive Maintenance Software, And How Does It Benefit Tugboat Operations?

Predictive maintenance software uses data analytics and machine learning to forecast equipment failures before they occur. By analysing real-time data from sensors installed on tugboats, the software helps operators anticipate maintenance needs, reducing the frequency of unplanned repairs and extending the lifespan of the vessels. This proactive approach not only enhances safety and reliability but also optimizes the tugboat work schedule, minimizing downtime and improving overall efficiency.

How Does Predictive Maintenance Impact The Tugboat Work Schedule?

Predictive maintenance allows for maintenance activities to be scheduled based on the actual condition of the equipment rather than predetermined intervals. This approach ensures that maintenance is performed only when necessary, avoiding unnecessary downtime and disruptions to the tugboat work schedule. By aligning maintenance activities with operational needs, tugboat operators can maximize uptime and ensure their vessels are always ready for service.

Can Predictive Maintenance Software Reduce The Cost Of Tug Boat Repairs?

Yes, predictive maintenance software significantly reduces tug boat repair costs by identifying potential issues before they escalate into major problems. Early detection allows operators to perform timely, less costly interventions rather than dealing with expensive emergency repairs. This cost-saving aspect of predictive maintenance not only lowers the overall maintenance expenses but also contributes to the profitability of maritime operations.

How Do LionRock And Techbinder Enhance Predictive Maintenance For Tugboats?

LionRock, in collaboration with Techbinder, offers an advanced Tugboat Tracker System that integrates real-time data acquisition with predictive maintenance software. Techbinder’s sensors and data loggers monitor key metrics like engine performance and fuel consumption, providing critical insights into the vessel’s condition. LionRock’s analytics platform then processes this data to predict maintenance needs, allowing operators to optimize their tugboat work schedule and perform maintenance only when necessary. This partnership ensures a comprehensive, data-driven approach to tug boat repair and maintenance, maximizing operational efficiency and vessel longevity.

Get more information

References

References For Predictive Maintenance Software

- How predictive maintenance can benefit the marine sector

- What is preventative maintenance?

- Recent advancements in data-driven methodologies for the fault diagnosis and prognosis of marine systems: A systematic review

- Big Data Analytics and Machine Learning of Harbour Craft Vessels to Achieve Fuel Efficiency: A Review

Image References

Photo of Tugboat: Maksym Kaharlytskyi

https://www.mdpi.com/2077-1312/9/12/1351

Get Started Today

Improve your maritime towage operations today.

Schedule a demo to see how our tugboat analytics can help you grow your business ahead of competition and save operational costs.